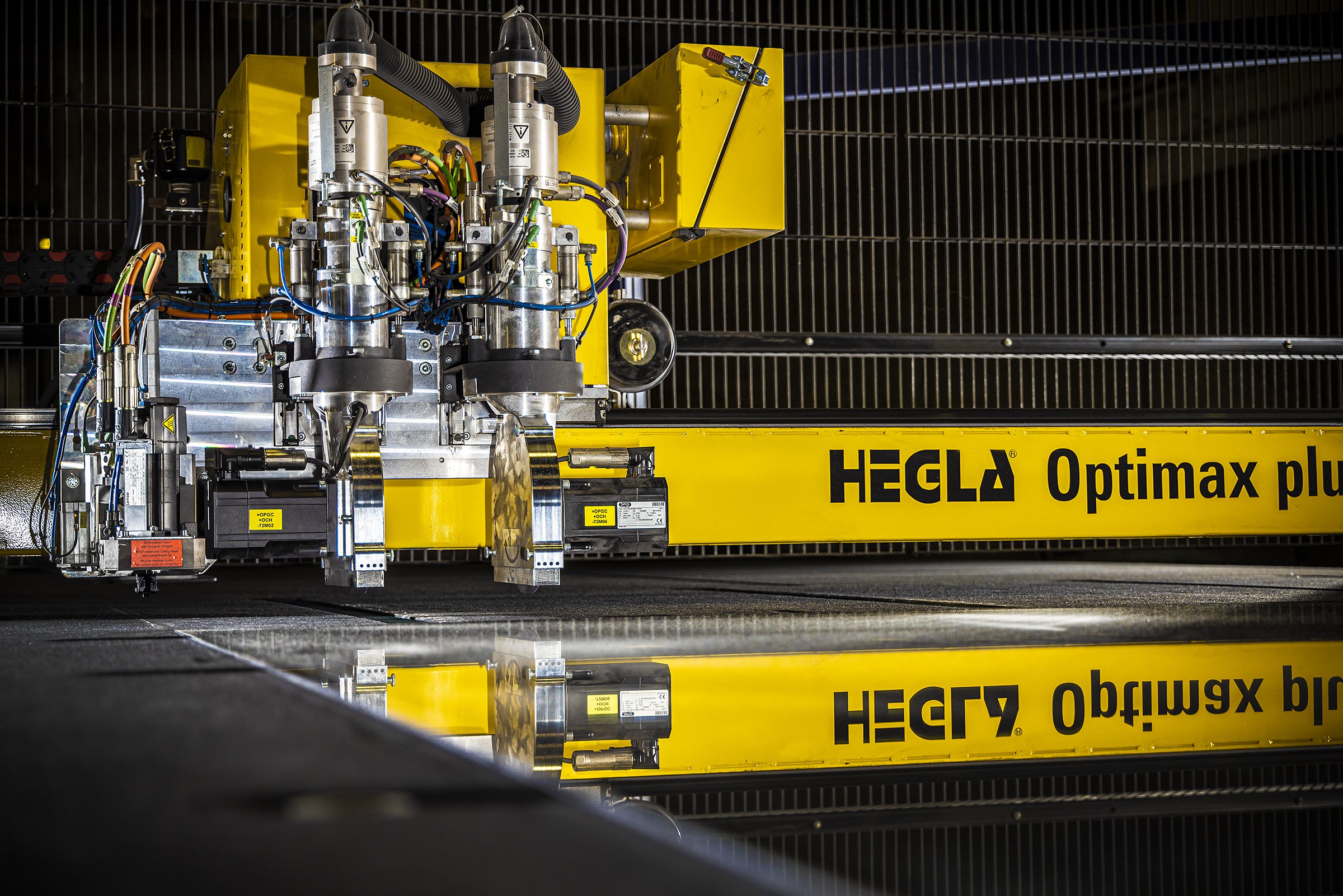

Hegla Optimax helps Custom Glass’ Leading Market Position Remains Consistent

Since the installation of a HEGLA Optimax cutting table and a fully automated Rapidstore system at Custom Glass, the company has gone from strength to strength. Having steered a path through the pandemic and the associated issues that brought, the Custom team has been able to support its cus- tomers by providing consistently high quality products for large and small installations.

The company handles over 30 different glass types, manufacturing for the glass industry and with demand increasing for the Custom Glass range across both commercial and domestic sectors, pro- duction methods were simplified by HEGLA.

The initial CAD drawings created by HEGLA UK after site visits to the Liverpool based specialist glass manufacturer, allowed production areas to be adapted to better suit product flow across the factory.

For Jeff Hooson the investment in HEGLA has been worth it, with the right modern solutions in- stalled that have helped to increase productivity without the need to move any of the other equip- ment around.

Being familiar with the HEGLA brand, prior to installation, the Custom Glass team had great ex- pectations about their investment, with the company need to produce on average 14,000 IG units per week.

Operations Manager, Andy Vint knew that the HEGLA name was considered excellent, with innov- ative solutions available that would support the company’s growth and plans for the future.The product portfolio includes various types of coated glasses and senior management knew that in- vestment in proven, advanced equipment would take the company forward.

Since installation, the large glass selection now can be fed automatically from the Rapidstore to en- sure that the cutting machine is continuously fed. Faster cutting also means that the toughener can be kept well fed. With 18 shuttle storage positions and 5 bulk storage positions, more racks can be added to this modular installation should customer demand and product diversity need it. The sys- tem is also fitted with an “airlock” loading door, this enables the stock inside the Rapidstore to be re-filled whilst the machine is in full automatic operation.

Larger batch sizes can now be cut more quickly and a broader product range can be delivered in a considerably shorter timescale. This is helped by the Optimax table that is fitted with a laser mark- ing system, coupled with the high speed grinding system which is designed to handle all the new coatings.

Custom Glass has achieved steady and consistent growth since 1982 when the company first opened. Now, it is firmly established as one of the UK’s leading manufacturers of domestic glass and toughened safety glass.

With more than 45 years experience in the sector, Managing Director Jeff Hooson bought Custom Glass 16 years ago, after recognising the potential the company had in the marketplace.

Today, the new HEGLA system has increased efficiency by providing consistently high quality products. Custom Glass has gone on to develop a range of quality engineered, specialist glazed products that meet and exceed current industry standards.

Occupying a 75,000 sq.ft. manufacturing facility, Custom remains focused on customer satisfaction and develops products according to market demands and industry regulations.

The company’s ability to manufacture the best quality I.G. units with soft coat glasses and warm edge spacer as well as gas filling capabilities ensures that the range is manufactured in the most re- liable and effective way.

Jeff Hooson comments “With such a diverse product range it is essential we get things right for cus- tomers and we have to achieve this quickly. The Rapidstore allows us to store more specialist glass without downtime. HEGLA’s carefully planned adjustments enabled us to create excellent effi- ciency across all production departments.

The industry has faced some challenging times recently and so we feel obliged than ever to always try to do the decent thing - our suppliers are as much a part of that obligation as our in-house team, and we consider HEGLA a very reliable business partner.”

The national delivery run has expanded considerably for Custom Glass over the last few years, so investment in the fleet was essential to meet customers’ demands.

Jeff Hooson concludes, “HEGLA’s Optimax and Rapidstore has strengthened the entire production facility for Custom Glass, with the equipment giving us so many technical advantages.”

For more information on Custom Glass or the HEGLA brand please visit www.customglass.co.uk or www.hegla.com respectively.