Let’s be honest…

We made a simple promise on thermal performance. That all our products would meet the upcoming tightened Part L regulations introduced in the 2022 revision to Building Regulations.

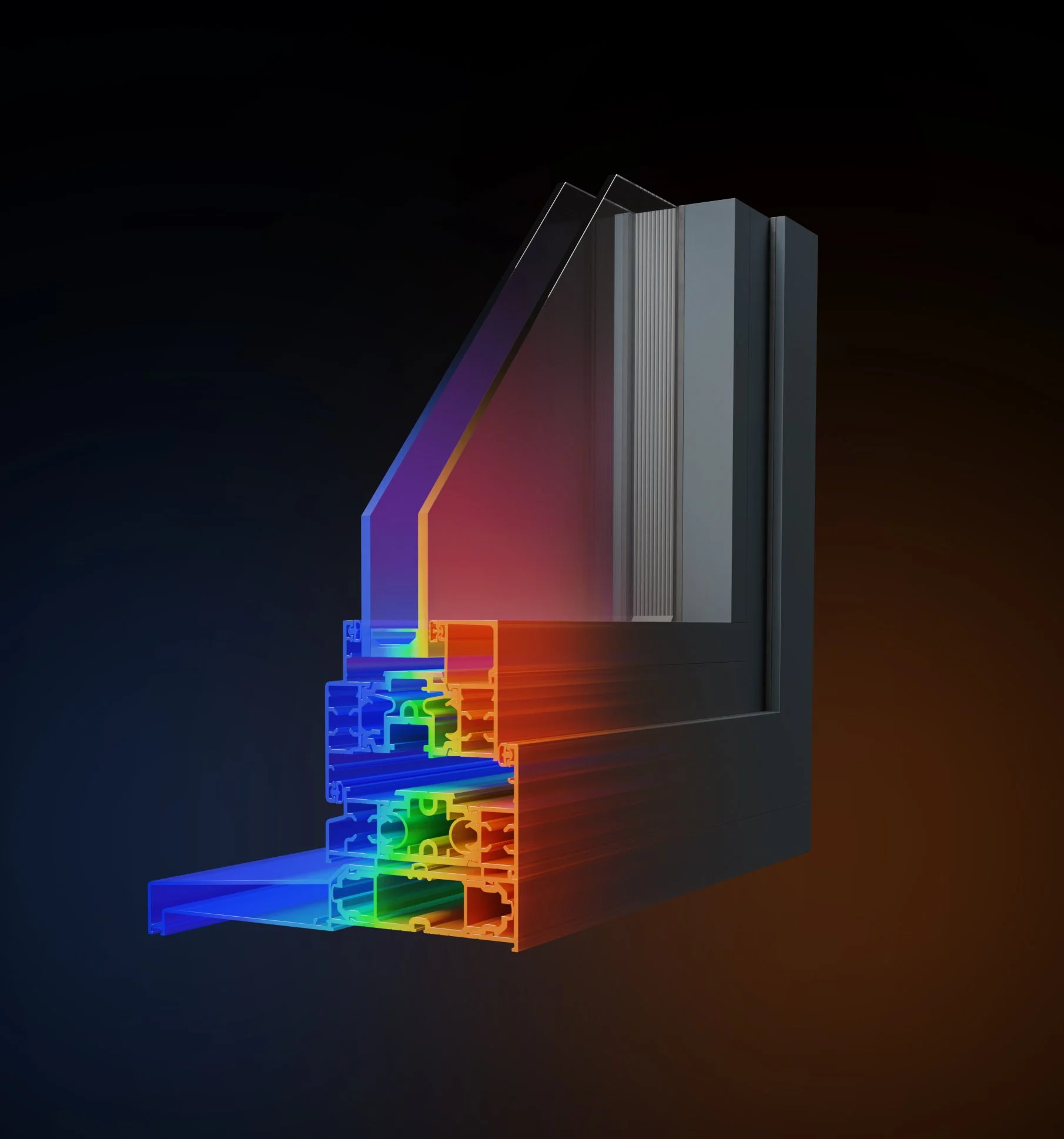

We achieved this by developing our own thermal break technology, Thermlock®.

Wider, multi-chambered and less conductive than legacy polyamide systems, Thermlock®, which sits at the heart of all Sheerline products enabled our customers to sell an easily understood range with consistent U-values that met these new targets with straightforward glazing requirements.

Our values are calculated to the EN14351 and BRFC standards, at the prescribed sizes and simulated with realistic combination of profiles and glazing that our customers actually use. All to give anyone choosing Sheerline aluminium products complete confidence.

Previously having operated in the PVCu market – this straightforward approach, this ‘honesty’ comes as second nature to us. In fact, when we started operating in the aluminium sector, we were a bit aghast at how murky, obfuscating and sometimes downright dishonest some claims were.

It’s time to change all that. That’s why we are calling for a tightening of standards and want to challenge our fellow systems companies to make their U-value reports publicly available, as we have. It’s time people know clearly what they are buying, as it’s their necks on the line.

Our challenge to the industry

• Publish independently verified U-value reports. As well as having two BRFC accredited thermal simulators in house, Sheerline also gets its U-value reports independently verified, which should be the gold standard across the industry.

It’s time industry bodies and building regulations made this compulsory.

• Stop selling products that don’t conform. The market tells us that many aluminium systems companies are paying lip service to these tighter thermal standards – claiming U-values based on a very ‘niche’ specification that rarely or never gets manufactured, then blithely carries on selling products they know don’t conform. It’s time that stopped too.

• Be honest and take responsibility. From systems companies ‘fabricating’ their U-value reports, to turning a blind eye to what their fabricators are making, to fabricators claiming U-values based on a spec of product they aren’t actually making. Everyone involved needs to take ownership and responsibility, making sure the companies supplying them are being honest and have the evidence to back up their claims.

We are heartened that other voices in the industry are beginning to pay at least lip service to bringing clarity to the subject of U-values in aluminium. Although as the tighter new standards came in over two years ago now, you do have to wonder how compliant their products were during that time.

Misrepresenting what you are selling can have disastrous consequences, just ask the Volkswagen group about its emissions scandal, or much more seriously the residents of Grenfell, and we are beginning to see window and door companies being taken to court for claiming one thing and supplying another. Pleading ignorance just won’t cut it.

Building inspectors and specifiers alike are increasingly adamant about seeing the evidence that backs up the thermal performance claimed. Those who get caught out can face compensation claims and legal bills that could cripple an otherwise healthy business.

Against these increasingly serious consequences, why take the risk?

Our U-value reports can be viewed on our website here. We don’t have anything to hide, if your systems house isn’t doing the same, ask yourself why.

Complying honestly doesn’t have to be complicated, it sometimes just needs a different way of thinking, or perhaps a different aluminium system supplier.